II. Driver Configuration

This section covers basic driver setup, including motor identification and parameter configuration.

Powering Up the Controller

- Connect battery (if not already connected)

- Activate power switch

- Verify motor sound indication

- Connect USB/CAN cable

- Verify Launchpad connection settings

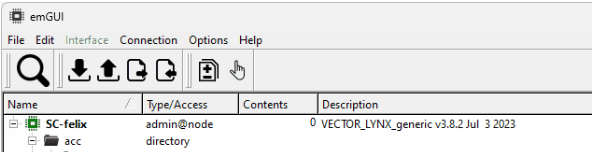

- Confirm controller detection in emGUI

Motor Identification

Covers the minimum to make the motor work. Required scripts are located in c:\silixcon\scripts\configuration\First_run\.

Alternatively, check the guided indentification

Sensor Configuration

Required only for VECTOR drive (FOC) firmware. Skip for BLDC firmware (BLDC supports hall sensors only).

Execute 1-Motor_sensor_selection.ys and follow prompts.

Script Functions:

- Controller authentication

- Sets

/driver/prestto specified value

Sensor support varies by application modification (mod). Details

Stator Current Configuration

/driver/iref: Maximum stator current [A] (amplitude, not RMS)/driver/ipeak: Must exceediref(recommend default value)

Motor Pole Pair Setting

Set /driver/motor/pp to motor's pole pair count. Required for accurate speed measurement and limiting.

Automatic Identification

Execute 2-Motor_identification.ys and follow prompts.

- Battery must operate within

ubminandubmaxlimits - Ensure unloaded motor with free rotation

Motor Thermal Protection Setup

Optional but recommended. Prevents motor thermal damage.

/driver/limiter/mtemplo: Initial limitation temperature/driver/limiter/mtemphi: Maximum limitation temperature

Values in [ohm] (motor temperature sensor resistance).

Monitor temperature via /driver/motor/Rthermistor.

Battery Limiter Configuration

Optional settings. Zero values disable DC-side voltage/current limitation.

/driver/limiter/ubmax: Maximum battery voltage/driver/limiter/ubmin: Minimum battery voltage/driver/limiter/ibpos: Maximum discharge current/driver/limiter/ibneg: Maximum regeneration current (negative value)

Rotation Direction

Vehicle forward direction is defined by spin-up rotation during the identrun procedure.

If you saw the opposite direction:

Change by wire swap

- Swap any two motor phases

- Requires re-identification

Change by parameter

Invert /driver/ipeak value:

- Forward:

/driver/ipeak= 200 [A] - Reverse:

/driver/ipeak= -200 [A]

Physical wire swap is preferred. Changing with ipeak can lead to unexpected vehicle reversing, if you lose the configuration with this setting.