Motor sensor

All settings related to the shaft sensor for electronic commutation in both vector and BLDC mode.

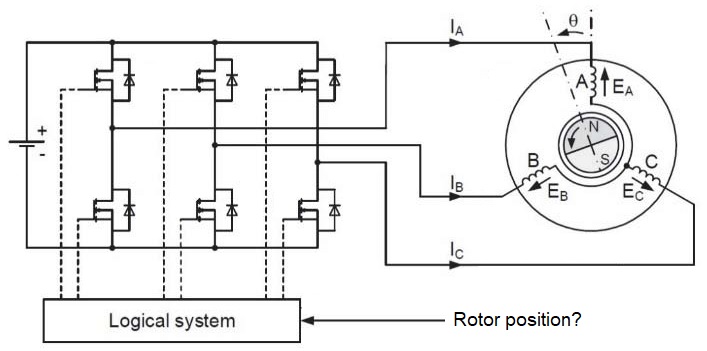

At the core of every PMSM motor control is the electronic commutation, a process that replaces the mechanical commutation found in brushed motors. To perform this electronic commutation effectively, the motor controller requires accurate information about the rotor's position at all times.

In other-than PMSM motor types (such as ACIM or stepper), the electronic commutation reduces into frequency generation (the electrical angle is decoupled from the rotor angle) and the accurate position of the rotor is no longer required. This can be activated by choosing 'prest' value 0 (asynchronous mode).

There are two primary methods for determining the rotor angle:

- Sensorless mode: This approach relies solely on electrical measurements from the motor's coils. By analyzing voltage and current patterns in the windings, the controller can infer the rotor's position without additional hardware.

- Sensored mode: This method uses a dedicated sensor mounted on the motor shaft to provide the rotor's position. The sensor continuously transmits this positional data to the controller through MSENS interface.

In the sensored mode, the ESCx controller constantly monitors validity of the incoming sensor reading. Fault check is implemented differently for each type of the sensor. Once a failure is detected, the power stage is immediately disengaged and the corresponding warning flag is raised in the /driver/stat word. Once the failure passes, the drive continues again. Therefore, we consider the sensor failure as a recoverable state. During failure, the algorithm can seamlessly switch into sensorless mode, if configured.

We strive to detect all kinds of different possible sensor failure modes, but it is not physically possible to guarantee the detection reliability at all times for all sensors. Please contact siliXcon for more information.

Each method has its advantages and trade-offs:

- Sensorless control can reduce system cost and complexity but may be less accurate at very low speeds. Although our proprietary method doesn't impose any constraints on the dynamic response and in some cases, it even surpasses the performance of sensored control at zero speeds.

- Sensored control may offer high precision (especially at low speeds), more reliable operation during motor overloading but increases system cost and introduces potential points of failure.

The choice between these methods depends on the specific requirements of the application, such as cost constraints, performance needs, and operating conditions.