Product specification

Physical characteristics

- width: 41.0 mm

- height: 102.5 mm

- thickness: 21.6 mm

- weight: 150 g

AX controller drawings and 3D models

General specification

| Parameter | value |

|---|---|

| Switching frequency | 20 kHz |

| Maximum motor magnetic field speed | 2 kHz |

| Minimum motor phase inductance | 2.5 μH |

Minimum motor inductance is inductance of one winding (half of inductance between motor terminals). Motor inductance usually drops with increasing current due to saturation of motor magnetic circuit. This effect must be also considered when evaluating motor minimum inductance.

If motor inductance is lower than specified, controller lifetime could be significantly reduced (even orders of magnitude). Low inductance increases electrolytic capacitors ripple current thus their temperature and lifetime.

Electrical specification

Input voltage rating

Maximum input voltage

| Voltage variant | Transistors | Maximum working voltage | Full limitation voltage | Critical error voltage (max) | Li-ion battery nominal voltage | Li-ion series cells count |

|---|---|---|---|---|---|---|

| 08 | 80 V | 60 V | 67 V | 75 V | 50.4 V | 14S |

Minimum input (supply) voltage

| Voltage variant | Transistors | Minimum working voltage | Threshold voltage | Critical error voltage (min) |

|---|---|---|---|---|

| 08 | 80 V | 24 V | 22 V | 15 V |

Terms explanation:

- The controller delivers maximal current without limitation if the battery voltage is below the Maximum working voltage and above the Minimum working voltage.

- The output current is proportionally limited if the battery voltage is above the Maximum working voltage and below the Full limitation voltage. This is indicated by the "Overvoltage" status.

- The output current is fully limited if the battery voltage is above the Full limitation voltage and below the Critical error voltage (max). This state is indicated by the "Overvoltage" status. The controller automatically recovers if the voltage falls below the Full limitation voltage.

- The controller falls into critical error if the battery voltage exceeds the Critical error voltage (max). The controller can be permanently damaged in this region and does not recover automatically, it needs to be turned OFF and ON again.

- The output current is proportionally limited if the battery voltage is below the Minimum working voltage and above the Threshold voltage. This is indicated by the "Undervoltage" status.

- The output current is fully limited if the battery voltage is below the Threshold voltage and above the Critical error voltage (min). This state is indicated by the "Undervoltage" status. The controller automatically recovers if the voltage rises above the Threshold voltage.

- The controller falls into critical error if the battery voltage falls below the Critical error voltage (min). The controller does not recover automatically, it needs to be turned OFF and ON again.

DC bus capacitance

| Voltage variant | Capacitance [uF] |

|---|---|

| 08 | 384 |

Output current and power rating

- VECTOR driver

- BLDC driver

If you put the controller to heatsink with 60°C temperature, you can reach the following nominal (continuous) parameters.

| Nominal parameters | 06dxa0810, 06kxa0810 | 05dxa0810, 05kxa0810 |

|---|---|---|

| Maximum power dissipation (60°C heatsink) | 29 W | 29 W |

| Nominal power for maximum input voltage | 2.60 kW @ 60 V | 2.44 kW @ 60V |

| Nominal phase current | 50 A (35.5 Arms ) | 47 A (33 Arms ) |

| Battery current | 43.7 A | 41 A |

If the controller is at 35°C, you can reach the following peak parameters for 10 seconds.

| Peak parameters | 06dxa0810, 06kxa0810 | 05dxa0810, 05kxa0810 |

|---|---|---|

| Peak power (10 sec) | 3.37 kW (dP = 46 W) | 3.11 kW (dP = 46 W) |

| Peak phase current(10 sec, amplitude) | 65 A | 60 A |

If you put the controller to heatsink with 60°C temperature, you can reach the following nominal (continuous) parameters.

| Nominal parameters | 06dxa0810, 06kxa0810 | 05dxa0810, 05kxa0810 |

|---|---|---|

| Maximum power dissipation (60°C heatsink) | 29 W | 29 W |

| Nominal power for maximum input voltage | 2.97 kW @ 60 V | 2.82 kW @ 60 V |

| Nominal output current (amplitude) | 49.5 A | 47 A |

| Battery current | 50 A | 47.4 A |

If the controller is at 35°C, you can reach the following peak parameters for 10 seconds.

| Peak parameters | 06dxa0810, 06kxa0810 | 05dxa0810, 05kxa0810 |

|---|---|---|

| Peak power (10 sec) | 3.84 kW (dP = 46 W) | 3.66 kW (dP = 46 W) |

| Peak phase current(10 sec, amplitude) | 64 A | 60 A |

| Phase current limit values * | Variant independent |

|---|---|

| Motor standstill (limited by hardcoded I2R limiter) | 60 A |

| Motor rotating (limited by hardcoded I2R limiter) | 85 A |

* When motor is rotating, power losses are equally divided between all three phases. This significantly reduces risk of single phase overheating and the controller is able tu supply higher current.

Measurement accuracy

| Measurement | Accuracy |

|---|---|

| Phase current | ±5 % |

| DC current | ±5 % |

| Input DC voltage | ±5 % |

| GPIO input voltage | ±2 % |

Thermal specification

Maximum power losses

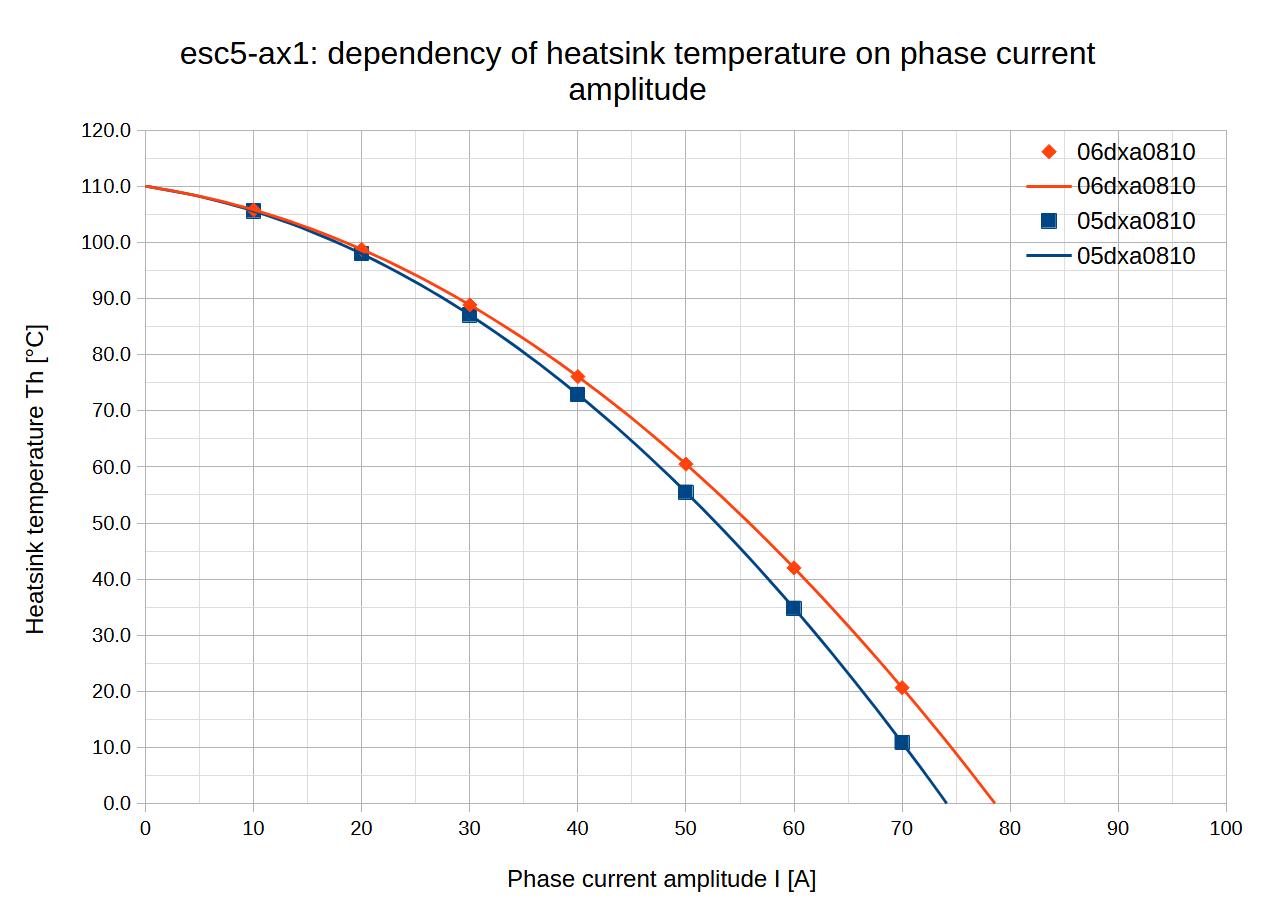

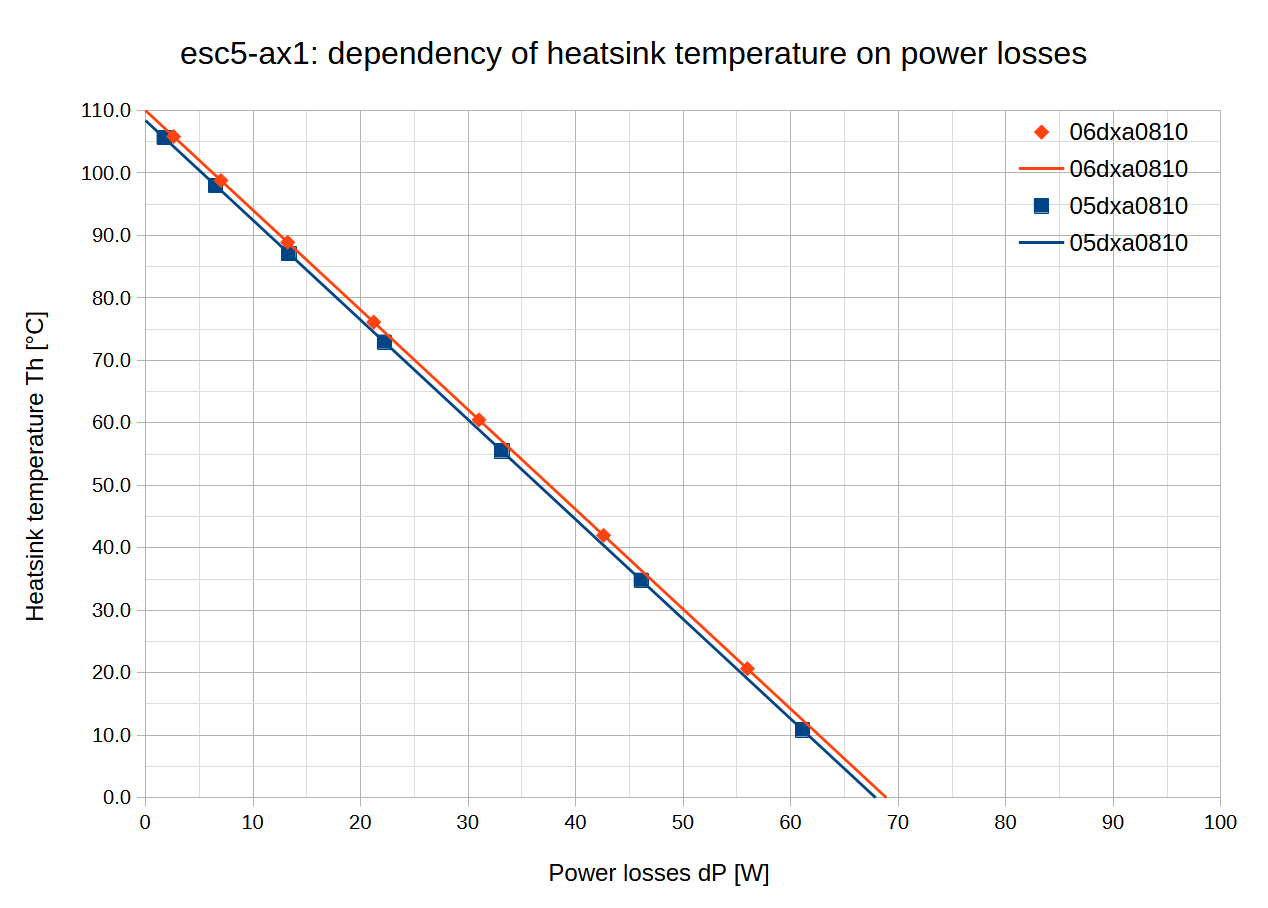

Controller maximum temperature is internally limited to approximately 100°C. The maximum output current (or maximum power losses) for this limiting temperature is given by the temperature of the heatsink. Dependencies are given in the following graphs.

All the data in the graphs below are valid for VECTOR control algorithm.

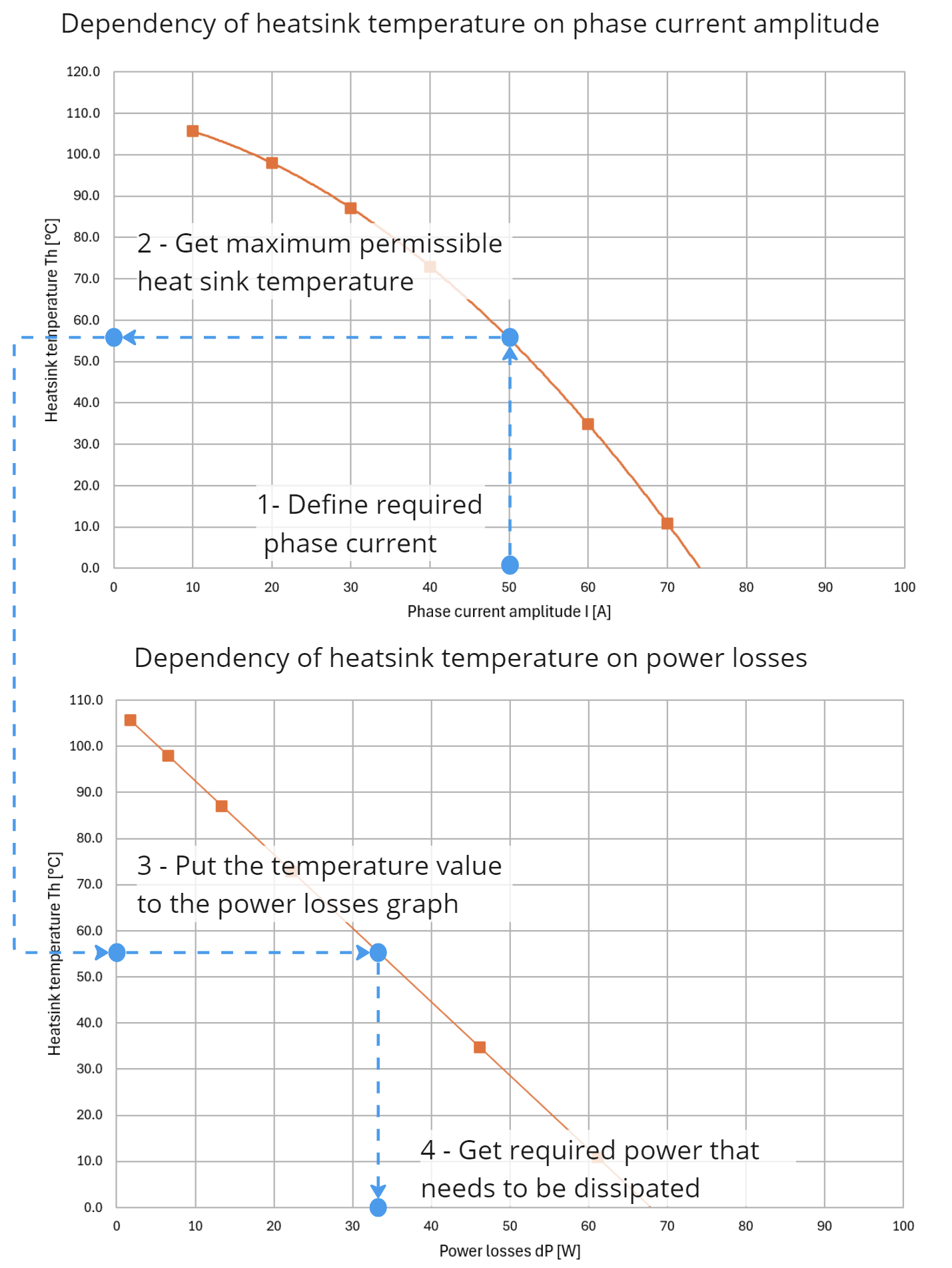

Example on how to get heatsink thermal resistance

This example with AX controller shows on how to get required heatsink thermal resistance based on the required phase current amplitude and surrounding temperature.

- Define the required phase current ( A for the example)

- Get maximum permissible heatsink temperature from the graph "Dependency of heatsink temperature on phase current amplitude" ( from the example)

- Put the temperature value to the graph "Dependency of heatsink temperature on power losses"

- Get required power that needs to be dissipated by the heatsink ( W from the example)

- Define the ambient operating temperature ( °C for the example)

- Calculate required thermal resistance of the heatsink by using this equation °C/W

- You can design your heatsink now!

Power losses calculator

Controller power losses are affected by the two main factors: motor phase current and DC link voltage. The following calculator can be used for rough estimate (~10% accuracy) of power losses in the controller. Calculation is valid for VECTOR driver.

Environmental specification

| Parameter | Value |

|---|---|

| Operation temperature (no limitation*) | -20°C .. 60°C |

| Operation temperature (with power limitation*) | -20°C .. 85°C |

| Humidity | 5 % .. 85 % (not tested) |

| Ingress of dust and water (internal electronics) | IP67 - electronic is potted in silicone |

| Ingress of dust and water (power connectors) | IP40 - connectors connected |

| Ingress of dust and water (signal connector, without sealing) | IP10 |

| Ingress of dust and water (signal connector, with sealing) | IP55 - It withstand 10 minutes 10cm under water. |

*power output limitation depends on cooling, not only on ambient temperature

Standards compliance

EMC

| Subject | Standard |

|---|---|

| Bulk Current Injection | ISO 11452-4: 2020 |

| Radiated Immunity | ISO 11452-2: 2019 |

| Radiated Emissions | ČSN EN 55025, ed. 3, art. 6.5 |

Mechanical tests

| Subject | Standard |

|---|---|

| Sinusoidal vibration | ČSN EN 60068-2-6 ed. 2, test Fc* |

| Vibration test | ČSN EN 60068-2-64 ed. 2, test Fh** |

*Sweep rate: 1 oct./min; Number of Test Cycles: 20 sweep cycles each axis; Axes of vibration: 3 (X, Y, Z); Acceleration profile according to Class 5M3 (ČSN EN 60721-3-5); Requested sine acceleration profile: 7.5 mm for 2 Hz ≤ f ≤ 8 Hz, 20 m/s2 for 8 Hz < f ≤ 200 Hz, 40 m/s2 for 200 Hz < f ≤ 500 Hz

**Acceleration profile according to Class 5M3 (ČSN EN 60721-3-5); Requested ASD level: 3.0 (m/s2)2/Hz for 10 Hz ≤ f ≤ 200 Hz, 1.0 (m/s2)2/Hz for 200 Hz < f ≤ 500 Hz; Effective acceleration: 29.5 m/s2; DOF: 190; σ-clipping: 3; Pre-test acceleration levels: -9 dB for 4 min 30 s, -6 dB for 15 s, -3 dB for 15 s; Duration: 8 hours each axis; Axes of vibration: 3 (X, Y, Z)